This process is experimental and the keywords may be updated as the learning algorithm improves. These keywords were added by machine and not by the authors. A review of creep parameters and models of polycrystalline ceramics is given in. The creep rates are governed partly by the properties of the grain boundaries and partly by the plastic properties of the crystal grains, the latter of which are discussed in this chapter. The maximum draw ratio is approximately proportional to the thickness of the lamellae. The drawing is accompanied by distinct necking, with a large decrease in the thickness of the mat and a very high maximum draw ratio, sometimes over 30. At high temperatures, the materials creep. Drawing is possible at temperatures higher than about 90C.

#Singlecrystal drawing crack#

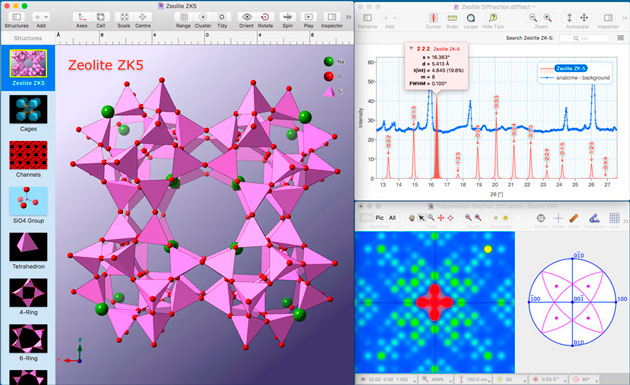

At low temperatures, their strength is limited by the brittleness, which is controlled by flaws in the polycrystalline structure acting as crack nuclei. Structural applications of ceramic materials are mostly in the form of polycrystals.

Presented a review of the dislocation and deformation properties.

Typical examples of ionic crystals and oxides are presented in this chapter. On the other hand, the ceramic crystals with strong covalent bonding become plastic only at high temperatures. On the one hand, these quantities are low in the alkali halides so that the Peierls mechanism controls the dislocation mobility and the flow stress only at low temperatures. Correspondingly, the Peierls stress and the double-kink formation energies are very different. Ceramic single crystals span a very wide range of materials from ionic crystals like the alkali halides with ionic bonding over oxides with mixed bonding to the carbides or nitrides with strong covalent bonding.

0 kommentar(er)

0 kommentar(er)